The Art and Science of Ice Water Hash

Hash being sieved for final stage packaging at Emerald Sun Hashery, Mendocino County, CA

Sponsored by Shish

Mention the phrase “solventless” to any cohort of cannabis connoisseurs and you’ll open a world of microns, terpenes, dab rigs, and rosin. Herein lies the driver of modern cannabis culture. Its members are a passionate community of tastemakers and artisans, rediscovering the centuries old tradition of hashmaking. And California is on the frontlines of the conversation and production.

The problem in today’s market: saying “solventless” could just as easily prompt looks of confusion from peers, consumers, and even cannabis business owners. Such is the learning curve of solventless cannabis concentrates and its endless downstream products.

But, the scales of the marketplace are tilting toward the connoisseur here.

In 2023, cannabis sales tracking platform BDSA Analytics asked, “Is Solventless the New King of Premium Concentrates?” It was a good question: With rosin products claiming a 21% share of dabbable concentrates sales in January 2023, the implied answer was YES.

Zoom into California’s marketplace, which is historically a major influencer in the broader U.S. landscape: Rosin products were found in more than 13% of all customers’ online baskets–up from just 10% the year prior. And while “rosin,” as a solventless category, led the sales figures for 2023, hash, bubble hash, and kief products also saw a boost, according to BDSA.

With cannabis consumers of all experience levels working their way up a steep learning curve, it’s helpful to understand how all of those premium, chemical-free hash and rosin products are made.

The story of solventless cannabis concentrates production is not complicated. Take Ice Water Hash as an example (Hint: half of the story is in the name).

Here’s what goes into the ice water aka bubble-hash production process, which in turn leads to the development of your favorite solventless edibles, rosin, solventless vape carts and much more.

Sourcing the Finest Cannabis for Solventless Extraction

How is ice water hash made, anyway?

The foundation of exceptional ice water hash lies in the careful curation of cannabis flower buds or trim. The quality of the starting material significantly influences the flavor, aroma, look and potency of the final product. To stand out in a crowded field, hashmakers must also choose strains with desirable cannabinoid and terpene profiles for well-rounded concentrates.

Hash (and rosin) can be made from freshly frozen cannabis buds or cured flower or trim. Some prefer cured flower for the best hash results, but “fresh frozen” flower currently defines the premium solventless concentrate market. Interestingly, not all cannabis worth cultivating for cured flower are necessarily great hash strains, and vice-versa.

Mother plants are raised and selected at a nursery for hash production, Mendocino County, CA

Selection of Premium Cannabis Material

Experienced hash makers must work directly with cultivators to breed, select, and harvest resin-rich strains at peak ripeness for optimal hash yields and performance. The sticky resin sought by hashmakers is produced by trichomes, bulbous glandular structures covering the plant which contain active cannabinoids with all of its desired effects and benefits.

Delicate Harvest

Being gentle is key. Handling the actual plant material with care is important as the harvest process sets the stage for the preservation of the delicate resin glands to be separated from the cannabis plant in the next stage of production, or the “wash”. Popular hash cultivars known for good yields and effects include GMO and OG Kush. Sungrown flower is also known to produce exceptionally high hash yields with unique terpene profiles.

Close-up image of resin-producing trichomes - the resin glands will shift in color from milky to amber during harvest.

Cold Agitation Is the Name of the Game

The harvested plant material is then agitated in icy water, or “washed” to break off the resin heads from the plant material, much like the spin cycle on a washing machine. The low temperature of the water and ice-vortex helps to separate the resin from the buds.

Legendary hashmaker Frenchy Cannoli aptly described this step in the process like shaking the fruit from a tree. Here is where the experienced artisan showcases their skill. The goal is to get the best yield from the plant without “overwashing” and potentially introducing lower quality plant material into the finished product.

Freeing Trichomes Through Movement

The submerged cannabis material is agitated, which when done manually is very labor intensive, or more increasingly with the help of modern purpose-built washing tanks. This agitation causes the trichomes to break away from the plant material due to that fragility rendered by the ice-cold water. This step is vital for separating the resinous trichomes from the plant matter.

Gentle Handling for Quality Preservation

Again, this is a delicate process. Care is taken to ensure that the agitation is not overly forceful, as this could lead to the inclusion of unwanted plant material or the breakdown of trichomes. (Remember, at each stage in this process the team will encounter both art and science, craft and technical prowess.) High quality washing achieves separation while maintaining the integrity of the resin glands.

Loose Flower or Bag Washing

Some hashmakers wash the flower material “loose” i.e. placed directly into the water along with the ice. Others prefer to pre-load the material into filtration bags first. The choice to use filtration bags in this process is part Art and Science. Bags offer greater control and are less likely to lead to contamination of plant material. Whereas loose washing is more efficient but does require post-production cleanup of biomass from the wash tank.

Filtration for Top-Tier Quality

The slurry mixture of water, extracted trichomes, and plant material is then filtered through a series of screens with varying mesh sizes (measured in microns). The screens allow water and unwanted plant material to pass through while retaining the tiny resinous trichome heads.

Hashmaker scooping out wet hash after the excess water has passed through the micron bag.

Gradation of Mesh Sizes

Multiple screens with varying mesh size, or microns seen as a “µm,” are often used in a sequential manner, with each screen capturing trichomes of different sizes. Most bag kits range from 20µ-220µ with 4-8 bag sizes in between, depending on your production goals. Micron sizes can vary from producer, but the general concept remains the same regardless of exact bag size used.

Grading for Quality and Use

Sieving with different micron bags allows for the collection of a spectrum of trichome sizes, contributing to the complexity of the final product. Every grade has a different quality but all grades serve a unique and valuable purpose in production, from your full-melt dabbing quality (73µ) to your edible grade hash (150µ) to your smoking grade hash (120µ). An interesting note is the best temple balls or pressed hash is often made by recombining all of the grades back together for the best representation of the original flower material from where it came.

Drying and Curing Is Where the Magic Happens

Once the sieved hash is collected on trays, the material will look like wet sand. The wet hash must be dried in order to consume the hash or to be able to continue the production process into an edible infusion or pressed into rosin. Excess moisture is carefully removed to prevent mold and preserve the quality of the hash.

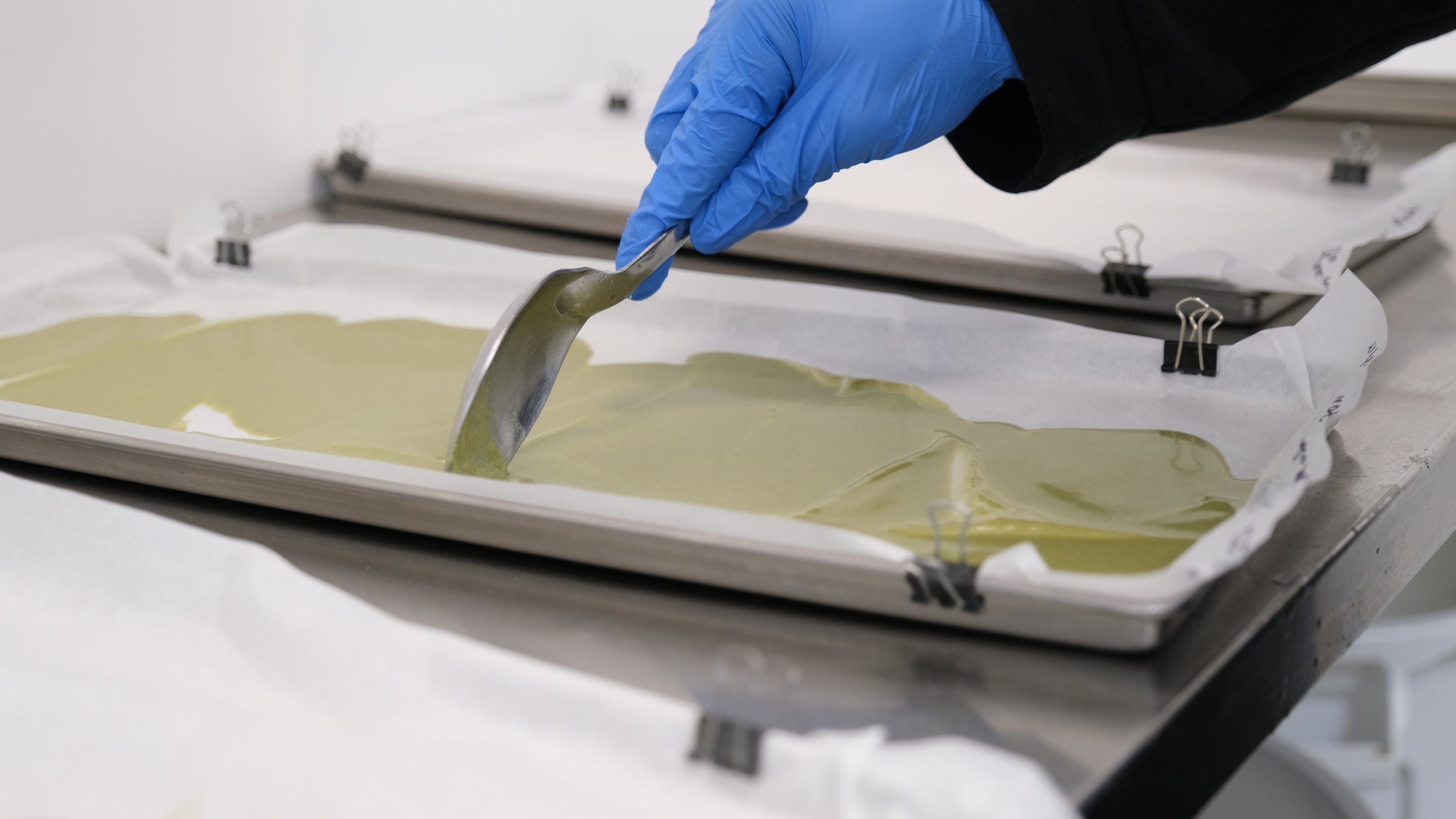

Post-micron bag, this wet hash is on a tray being prepared for freeze drying.

Freeze Drying v. Air Drying

Drying is critical, and there are two main ways to accomplish this task while preserving the quality of this hash product. Freeze drying is an efficient process that sees the hash material placed in a vacuum and frozen by water vapor (thus immediately preserving the quality of the trichomes in the hash). Air drying is the more traditional process, in which the material is laid out in an environment with good airflow (similar to how cultivators will hang-dry their recently harvested colas) to draw out the moisture.

Curing for Flavor and Potency

The dried hash is then cured, a critical step in achieving a well-rounded and enjoyable hash. The exposure process takes the hash through several forms, beginning as glassy hard and brittle, slowly becoming sticky/pasty, and then the most common form for classic bubble hash is a fine sandy consistency. If the material is exposed to too much heat it will revert back to a hardened sticky form and can darken in color. The use of ice water and cold conditions from the beginning helps to preserve the quality of the trichomes as heat can degrade these fairly sensitive compounds. The resulting ice water hash is a high-quality concentrate, free of extraneous solvents, with a potent and flavorful profile.

Head Hashmaker sieving cured hash at Emerald Sun Hashery, Mendocino County, CA.

Now It’s Your Turn

What customers might see on shelves or hear from knowledgeable budtenders is a tiered system ranking these end products: a star-based ranking, from one-star to six-star hash.

This can be highly subjective, but there’s a basis in reality and an importance to this system. (Again, go back to that idea of sparking a conversation about “solventless” cannabis with a ring of connoisseurs. In that type of crowd, enthusiastic subjectivity is a guiding principle.)

1-2 star hash is mostly utilized as edible grade material. 3-4 star hash is great smoking grade material for pre rolls or bowls mixed with flower, and at the 5-star and 6-star hash levels, you’re working with very high-quality material suited for dabbing directly. That quality is predicated on each of those stages that the material went through as it was being filtered and agitated; careful hash-making is an artisanal process. Five and Six-star hash, also known as “full-melt hash,” is a high-end product that leaves little to residue and bubbles/melts, not burns, upon contact with heat.

It's important to note that the terminology can vary, and different regions or individuals may use slightly different terms to describe similar processes or products. Ice water hash is a great example of a product that should elicit in-depth conversations with budtenders and deserves standardization to recognize quality and allow for consumer education.

As you’re learning about the products that come out of the hash-making process, this is an opportunity to demonstrate that cannabis business operators, too, can learn more about solventless products and, in turn, educate the California consumer base.

Hash-making is an ancient art (and science), and the modern-day California cannabis market is reviving the international culture with every wash. For every solventless product you encounter on store shelves, there's a hashmaker and a cultivator who are pioneering this old, new world.